Window Patching : A Package’s Store Front

Window patching is a common method for use in packing of consumer goods containing items such as toys and snacks for the purpose of display and the features of the product inside the box. However, this method can be applicable to any type of product. Additionally, consumers appreciate displaying expensive luxury goods through the opening of a client box in order to provide relief.

There is a sea of choices, and new information becomes available when you talk about putting a window box patch on retail packaging-the question is how to package your product so it becomes the top choice for consumers.

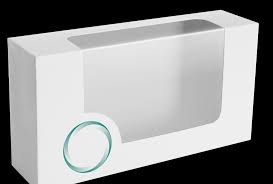

What is Window Patching?

Window patching is a fairly advanced packaging procedure that facilitates the placement of a window, for instance made of a clear membrane, on a pre-cut flap of a container or carton so as to permit the display of the incorporated in a purposely visible manner. The procedure is very common in such industries as food, pharmaceuticals and cosmetics and also retail marketing where consumer and marketing concerns dictate that the product be seen.

In the above mentioned sectors, it is in many times that the elements such as ingredients and the forms of the products require to be easily observed thereby necessitating window patching and it is not only limited to that as this method also attentively displays constructing the product lines attractively and in an appealing manner.

How Window Patching Works

And the window patching process is using precision and high-quality material then seamlessly apply it. The first process will be cutting out the surface area designated paperboard or cardboard box. A thin film is applied to the designated area. A clear see-through film is normally used, such as PET film or PVC film. By doing so, one is able to satisfy their clear view and protective status regarding the item that is about to be seen. This kind of operation is controlled by machines.

These machines are window patching machines that have specific characteristics, which are meant to ensure that the process is automated making it more or less perfect in terms of speed and accuracy.

Benefits of Window Patching in Packaging

- Enhanced Product Visibility – By allowing customers to witness the actual product in action before making a final decision, businesses establish a good and trusting relationship. Thinking positively, consumers will be swayed into buying the product.

- Improved Aesthetic Appeal – Sheer sophistication and elegance are thus revealed by transparent windows on cartons. This allows for better retail of the products inside the carton.

- Protects Against Contaminants – The product gets stopped from dust, water, or other pollutants through the films.

- Versatile Application – It is applied to industries such as baking, confectionery, electronics, and medical supplies.

- Sustainability Options – There a few window films that could be biodegrade or recyclable so that would—at least in a small way—reduce the carbon print on the earth.

Window Patching Machines : Key to Efficient Packaging

Since window patching is reliant on the performance of window patching machines, it can be seen that the complexity of this equipment is justified. These machines help to apply the wrapping films thereby ensuring extremely high quality. These are accessible in multiple specifications which are based on the brewing capacity and requirements of packaging.

Types of Window Patching Machines

- Manual Window Patching Machines – Suitable for small-scale businesses with limited production needs.

- Semi-Automatic Window Patching Machines – Balances speed and affordability for mid-sized businesses.

- Fully Automatic Window Patching Machines – High-speed machines designed for large-scale manufacturing.

PET and PVC : Common Types of Window Patching Films

Material selection for window patching is a matter of working for longevity, aesthetic appeal, and ecological best practices. The most common materials used in the present scenario are PET film, especially for its superior shimmering, frosty appearance, which is both inexpensive and eco-friendly.

PET Film

PET is a popular film used for transparent windows because of its availability density, ultralight weight, and convenient enough to use again and again. The material is sufficiently strong and in combat moisture and that is why it is preferred in food and pharmaceutical package manufacture.

PVC Film

One more popular choice is polyvinyl chloride (PVC) film because of its longer lasting features and ease of use. This film, though behaving well in the context of transparency has a minus in terms of being environmentally friendly rather than the pet film counterpart. Nevertheless, the packaging industry is known to extensively use PVC films because they tend to be high in tensile strength and are capable of resisting chemicals.

Custom Window Boxes : Tailoring Packaging to Your Brand

Window boxes designed to fit your specific bulks are more than just basic customized containers that you can use to put products in. When companies make the custom packaging with a window that means they can center most of their focus on the product and ensuring that it is displayed perfectly while offering safety and protection. These boxes are widely used for:

- Bakery and confectionery products

- Electronics and gadgets

- Pharmaceutical and medical products

- Luxury cosmetics and perfumes

Rigid vs. Flexible Windows: Which One to Choose?

Organization can place a window patch with flexible or rigid material according to product attributes and packaging objectives.

Rigid Windows

Rigid windows are normally paired with thick and tough material, making it good for maximum protection. Generally, it is ideal to be used in items within the high end market that require sophistication.

Flexible Windows

The variety seen in food packaging, tinted on the plate window in in all probability case does not plays a purely utilitarian role. In this case, the package stylist must choose in favor of presence of the window.

Future of Window Patching in Sustainable Packaging

The increasing interest of the consumers in eco-friendly products, the window patching sector is currently in the process of change to sustainable solutions. There are a few brands moving towards the biodegradable and recyclable window films in order to minimize the environmental impacts. The completely different level of greener packaging materials, thereby still innovating on the compostable PLA and other kinds of films.

Conclusion

The practice of adding windows to packaging improves the appeal, defense, and promotion of items. Installing clear window to packaging is beneficial to enterprises, irrespective of whether it is made from PVC film or PET film. Companies can optimize the effectiveness, performance, and greenness of their packaging through the use of state-of-the-art window patching machines.

The correlation between the exactness and effectiveness is intriguing too when comparing the bone dry work of the scientists who work on these seemingly charming creatures, to that of windowlickers. As much as the extinction of the panda scientist is fought in favor of viability, at the same time efforts in the packaging industry are being promoted to protect the environment and save the energy for the future generations.

It can be said that implementing window patching in this situation is not only about the enhancement of the appearance of the product but also falls side by side modern and ecological packaging movements, giving a double benefit to both entrepreneurs and nature.